Super Rigid Bridge Type Machining Centers

The highly rigid HTP series is equipped with a high torque spindle for outstanding heavy cutting performance. It can easily increase the chip removal rate, reduce cycle time and complete tough material machining easily.

Strong spindle unit structure

The U-shaped saddle design with four linear guideways and ten sliding blocks supporting the Z-axis gives the spindle head firm support. Even with the Z-axis fully extended, the machine can still maintain excellent machining accuracy.

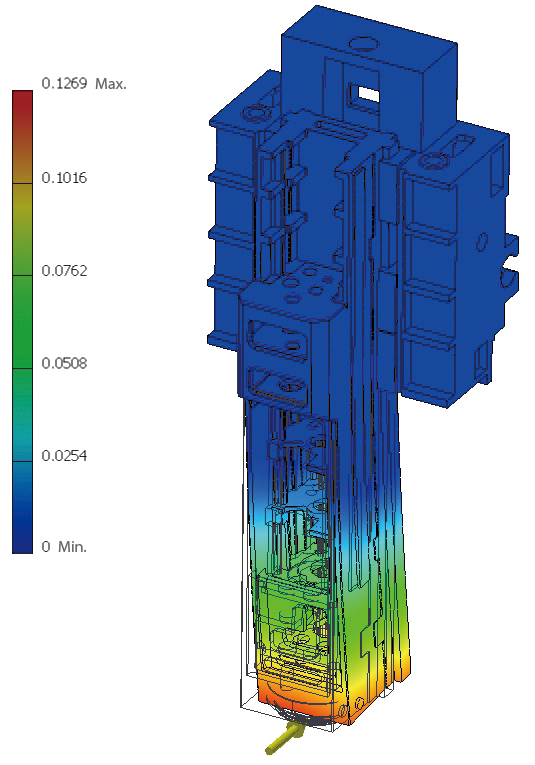

Standard Machine

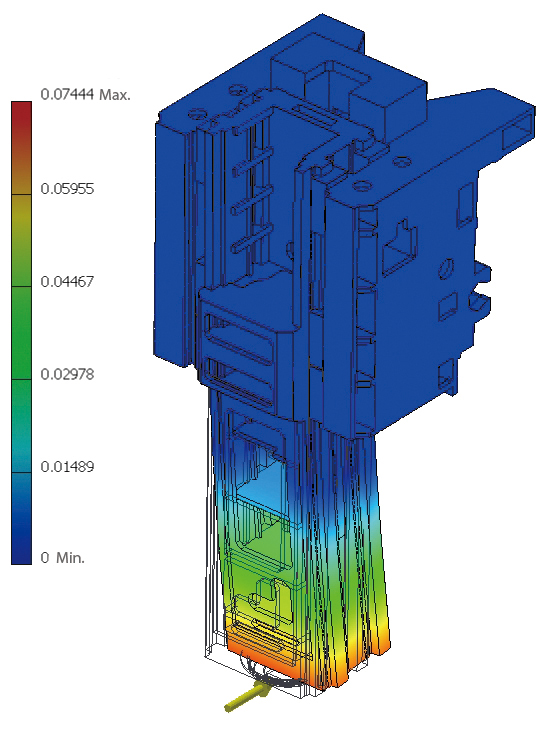

Standard Machine

Load:5,000 N

Max. displacement 0.1269 mm

AWEA HTP Series Machines

AWEA HTP Series Machines

Load:5,000 N

Max. displacement 0.0744 mm

The rigidity of the head structure has been increased by

Best linear guideway arrangement

High quality 4 linear guideways supporting the X-axis and 3 guideways supporting the Y-axis allow the HTP series to easily surpass its competition in structural rigidity, table load and accuracy.

Flexible multi-face machining capability

An automatic head changer and a two positions ATC system are optional upgrades for improved multi-face machining.

A new generation of in-house made attachment heads is available now.

Exceptional capability of chip removal and cooling

Standard two coil type chip augers and a caterpillar type chip conveyor efficiently remove chips. The coolant tank effectively reduces cutting fluid heating, thus ensuring better machining accuracy.