High Rigidity Structure

The Finite Element Method ( FEA ) provides the means to optimize the machine design and create a light-weight yet extremely rigid machine structure.

The structural designs of bridge and base have been optimized. The contact surfaces are precision hand scraped to ensure optimum assembly precision, utmost structural integrity, and enhanced load distribution.

The spindle heads' wide span symmetrical design, with the X-axis' ball screw placed at the center line of the axial movement, provides high precision axial feeding features and avoids yawing problems, as well as uneven wear of the guide ways, encountered in other machines due to their eccentric drive system design.

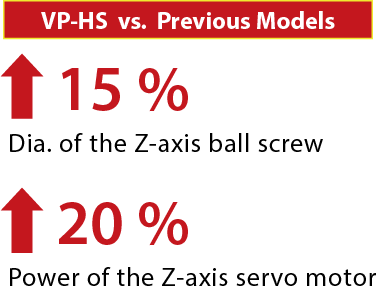

Brand new Z-axis drive system

Due to the powerful servo motor and the strengthened ball screw the Z-axis does not require a counter balance system. The design significantly improves the dynamic response and makes the VP-HS Series ideal for high precision mold making.