Optimum Spindle System

Centro-symmetric Spindle System

Centro-symmetric Spindle System

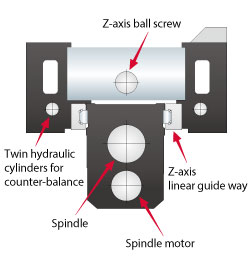

Unique head design allows the spindle, spindle motor, ball screw and dual hydraulic counter weight cylinders to be symmetrically placed. Hereby preventing thermal distortion and minimizing deflection. Assuring accuracy and heavy-duty cutting capability.

Powerful Cutting Capability

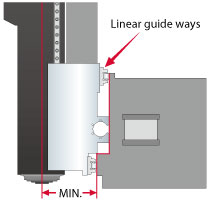

Inner-rail embraced structure provides high rigidity and good stress flow which minimizes over hang and vibration issues.

The Y-axis roller type linear guide ways offset from each other, increases structural rigidity and reduces distance between the spindle to cross beam which enhances overall cutting performance.

High Torque Gear Spindle

High Torque Gear Spindle

2-speed super heavy-duty gear box

Floating type hydraulic tool release device eliminates pressure on the spindle bearing when releasing a tool.

4,000 rpm high torque spindle is equipped with powerful 26 kW ( 35 HP ) motor, delivering maximum torque output of 977 N-m at 254 rpm which can meet with various heavy-duty cutting conditions.

5,000 / 6,000 rpm gear spindle ( Opt. )

![[+]](../../../../images/milling/production-bridge/lg/spindle/lg-spindle-4000rpm.jpg) High Speed, High Torque Built-in Motorized Spindle

High Speed, High Torque Built-in Motorized Spindle

The built-in motor design reduces centrifugal force effect and restrains spindle vibration, which increases the spindle life span and improves long-term machining accuracy.

Floating type hydraulic tool release device eliminates pressure on the spindle bearing when releasing a tool.

6,000 rpm and 8,000 rpm are available, which provides maximum 600 N-m torque output at 350 rpm to meet with various working conditions.

![[+]](../../../../images/milling/production-bridge/lg/spindle/lg-spindle-6000rpm.jpg)

![[x]](../../../../images/milling/production-bridge/lg/spindle/lg-spindle-4000rpm-zoom.jpg)

![[x]](../../../../images/milling/production-bridge/lg/spindle/lg-spindle-6000rpm-zoom.jpg)