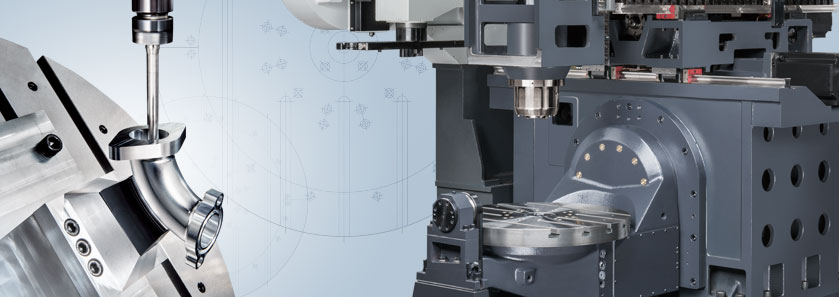

High Rigidity Structure

Guided by Finite Element Method and utilizing high tension Meehanite casting structure allow one-piece bed, column and saddle to reach optimal design. Mechanical strength of machine can sustain extremely heavy cutting while maintaining long-term excellent accuracy. As a result, high rigidity structure of FCV series can also extend the life time of the tool usage.

Movable column C-shape structure design provides the best structural rigidity and minimizes floor space at the same time.

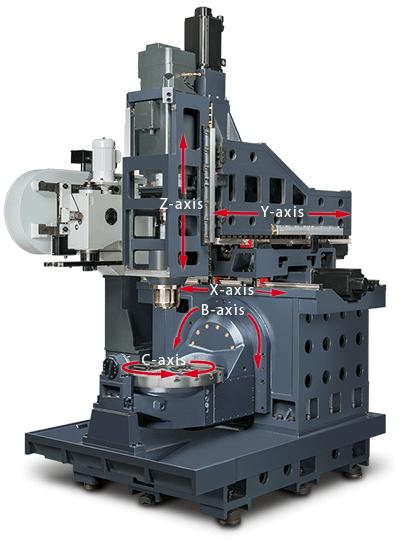

Column adopts one-piece thick ribs structure with 4 large-sized linear blocks on each side well support saddle which remains steady while fast movement machining on Y-axis.

All axes adopt roller type linear guide ways which unites heavy cutting capability of box ways, and fast movement and low wear capabilities of linear guide way.

X / Y / Z axes are direct drive by AC servo motor with absolute encoder, which provide powerful thrust and fast acceleration / deceleration movement with extreme accuracy.

X / Y / Z rapid feed rate 36 m/min

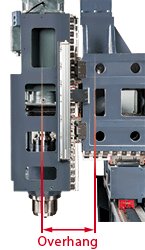

Extremely Short Spindle Overhang

Minimal spindle overhang design ensures structural rigidity of spindle and machining accuracy.

Linear Scale ( Opt. )

The optional high resolution close-loop linear scale ensures excellent positioning and repeatability accuracy.

Rotary Working Table

Advanced design of rotary table is unilateral driven and supported by both sides of structure to provide outstanding performance and accuracy.

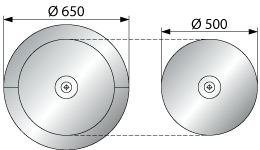

High Performance Rotary Working Table

Rotary table adopts one-piece spheroidal graphite casting iron which provides excellent ductility and great anti-vibration ability to ensure optimal machining accuracy.

Working table adopts detachable inner / outer plate design. Diameter of inner plate is Ø 500 mm. Depends on the size of work piece, the inner plate can unite with the outer plate, which diameter of plate can extend up to Ø 650 mm.

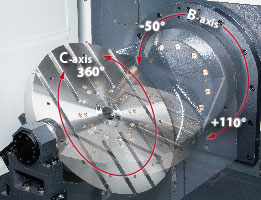

Ultra Performance B / C-axis

Ultra Performance B / C-axis