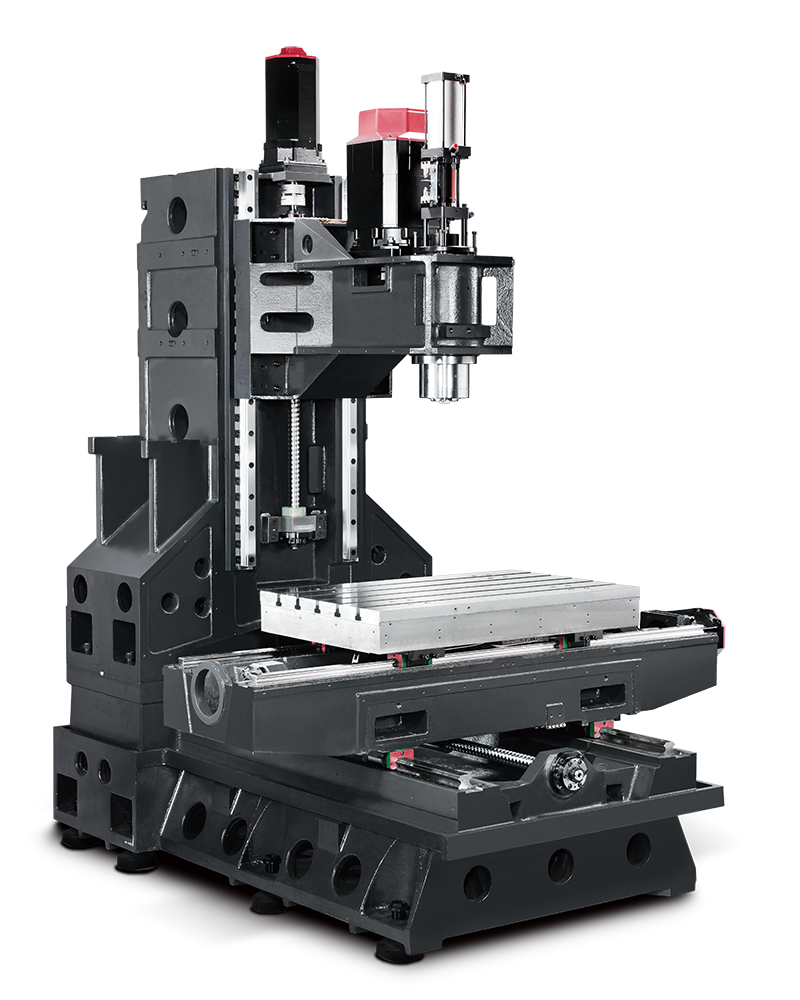

High Rigidity Structure

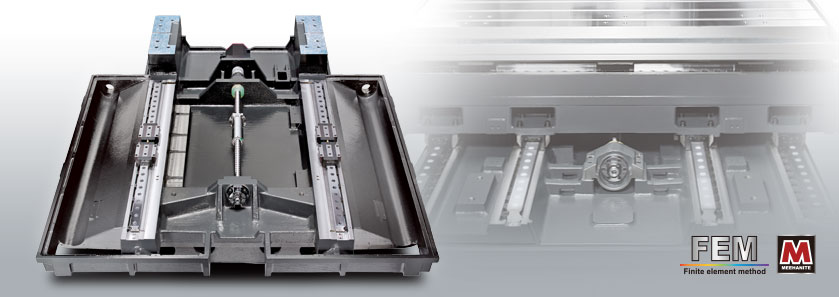

The Finite Element Analysis ( FEM ) provides optimal machine design, allowing us to create a

lightweight structure while ensuring the machine's high rigidity.

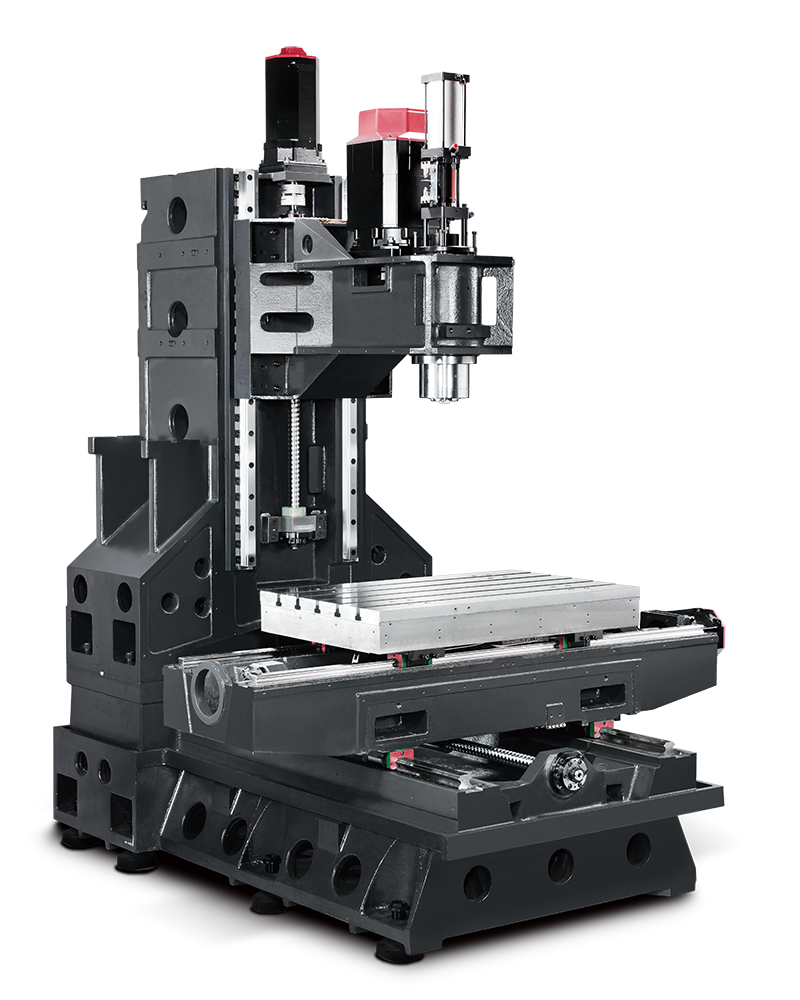

With a MEEHANITE casting bed and a Y-shaped column design, the structure offers superior

rigidity and vibration damping to ensure unmatched dynamic accuracy during high-precision

machining.

The △ ( Delta ) wide-span column structure provides optimal machining rigidity, while the

headstock maintains stability and accuracy during high-speed travel.

The contact surfaces of the column and bed are all hand scraped to ensure precision

assembly, strong structure, and even load distribution.

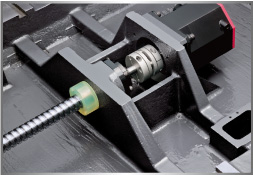

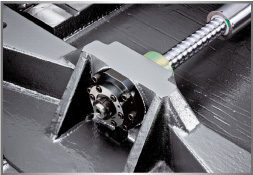

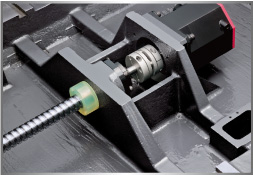

The servo motor mounts and the ball bearing supports are integral parts of the casting,

enabling even cutting force distribution into cast body, efficiently enhancing axial system

rigidity and preventing ball screw deformation.

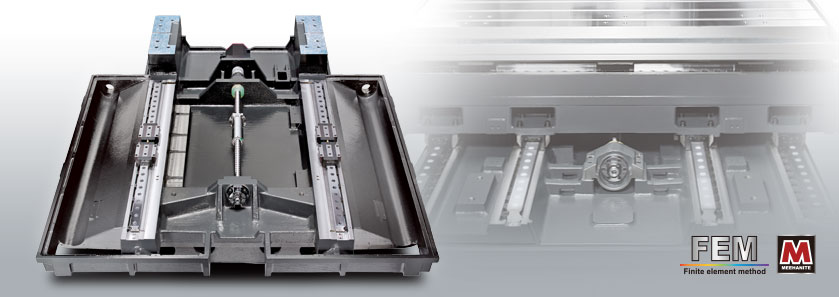

The saddle (Y-axis) travel of the AF-1400MAX, AF-1600MAX, and AF-1800MAX models is

supported by four linear guideways. The bed size is extended according to the saddle's

travel range to avoid overhang and ensure optimal support rigidity.

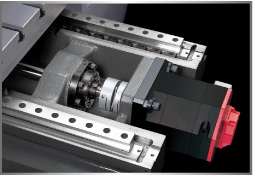

High rigidity roller type linear guide ways combine the heavy cutting ability from ground

box ways with fast movement and low abrasion, improving rigidity, agility, and control of

the machine.

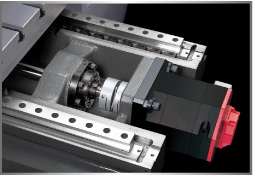

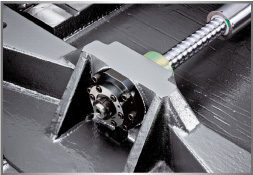

High precision dual-nut ball screws provide excellent heavy cutting rigidity while ensuring

machining accuracy and extended durability of the ball screws.

All three axes employ FANUC αi absolute AC servo motor direct drives, providing great thrust

and fast acceleration / deceleration. Plus, they efficiently decrease motor load and reduce

generation of heat while maintaining ultimate performance and accuracy.

HOME

Vertical

Milling

AF-Ⅱ Series

Overview

Structure

Spindle

Quality

Specifications

Dealer Network

Contact / Inquiry