Well Designed Operating Interface

Good splash guard design reduces the distance between the work area and operator, improving output efficiency and maintenance safety.

Based on an ergonomic concept, the rotatable control panel is designed to be on the operators left side, allowing for easy operation.

The distance from floor to work table is 1,180 mm; this allows workers to load the work-piece conveniently and easily.

The distance from the ground floor to the center of the operator screen is 1,620 mm, the average eye level, providing comfort to the machine operator.

Large impact resistant windows provide a convenient and safe operating environment.

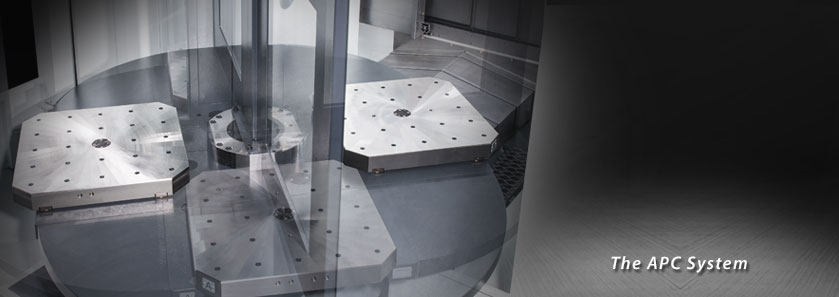

The APC System

The APC system has a servo motor driven 180˚ index table. It takes only 16 seconds for the pallets to change which can effectively reduce wait time and increase production.

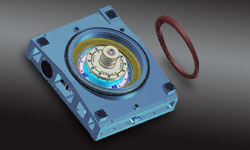

The clamping mechanism uses a four hydraulic cylinder and cone seat design which provides stable machine accuracy and ample clamping force to the work table.

The cone seat uses air blow cleaning and air pressure detection mechanism in order to enhance the clamping reliability and position accuracy.

0.001° B-axis indexing

0.001° B-axis indexing

High precision two-piece worm gear mechanism has contact teeth and contact area that are twice as more compared to conventional designs, ensuring table rotation accuracy and the ability to provide complex work-piece machining.

Hydraulic brake system with full circumference will help prevent deformation of the brake disks due to its high rigidity characteristics and heavy cutting durability.

1° B-axis indexing

High rigidity clutch indexing, positioning accuracy 8", repeatability 2", makes it suitable for heavy table load and heavy-duty machining.

Fast Auto Tool Change System

The servo driven arm-type ATC is highly efficient and reliable as all tool change motion and position are monitored by detection sensors and sequential scans. The T-T time is 3.4 sec.

Spindle tool clamp system is designed with solenoid flow control valve. The operation is stable and smooth, even with heavy tool.

It can be equipped with 60 ATC ( standard ) or up to 240 ATC to fulfill different working conditions.

High Efficiency Chip Removal System

The coolant flushing system around the spindle and roof can effectively flush chips away from the working area in order to ensure stability and precision of the machine.

The complete coolant chip removal system consists of two chip augers, chip conveyor and a large volume tank that can remove chips efficiently.