Super Rigid Structure

Finite Element Method• The Finite Element Method provides the optimal machine design to build a light-weight, yet super rigid machine structure.

Four guide ways on a U-shaped base

• The rigid U-shaped base with dual linear guide ways on each side provides a solid basis for the cross beam.

Heavy load fixed type work table

• The T-slots of the work table are finished at our factory after the machine set up and geometric accuracy adjustments have been completed to ensure perfect alignment.

Y-axis sectional guide ways design

Y-axis sectional guide ways design

• The Y-axis liner guide ways offset increases the structural rigidity and reduces the distance between spindle head and cross beam, thereby minimizing distortion and vibration issues, as well as enhancing overall cutting performance and accuracy.

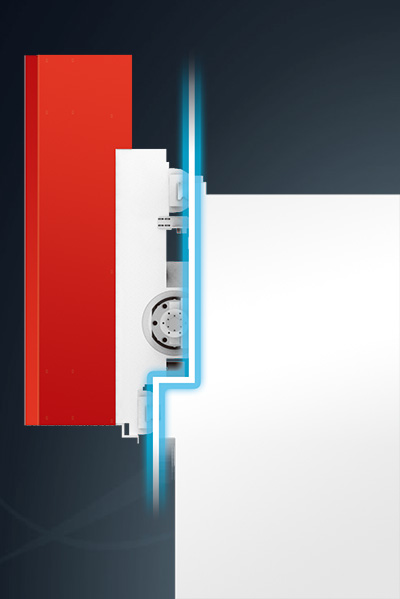

High rigidity roller type linear guide ways

• The super rigid roller type linear guide ways on the X, Y and Z axes provide heavy-duty cutting, fast movement and low friction capabilities.

High performance drive system on all linear axes

High performance drive system on all linear axes

• Direct-drive servo motors on all linear axes deliver ample thrust and dynamic responses.

• The X-axis is equipped with one linear scale on each column to ensure utmost accuracy and perfectly parallel movements.

• The Z-axis is driven by dual ball screws and servo motors without a hydraulic counterweight system for superior dynamic response.