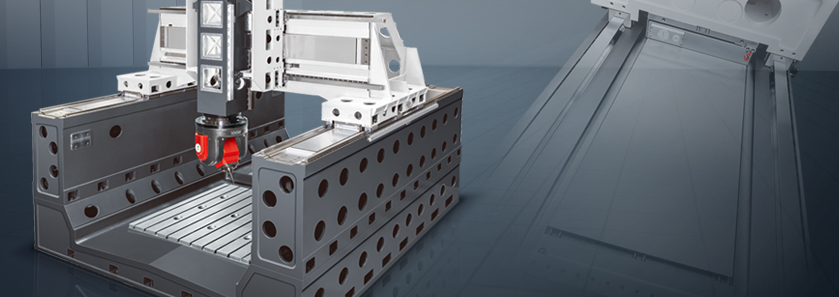

Super Rigid Structure

• The highly rigid U-shaped machine base provides shock dampening and extremely low deformation properties. It offers excellent support for all moving members even under high-speed and heavy cutting conditions.

• The X-axis is supported by 4 linear guideways and 12 sliding blocks, that provide excellent rigidity and enhance accuracy.

• The highly tensioned Y-axis' box structure with special light weight rib enhancements provides the structural rigidity needed for heavy cutting. It reduces the inertia during high speed movements and adds significantly to the dynamic response ability of the X-axis.

• The super rigid roller type linear guide ways on the X, Y and Z axes provide heavy-duty cutting, fast movement and low friction capabilities.

Symmetrically arranged servo drive motors

Symmetrically arranged servo drive motors

• The Z-axis adopts a dual drive system with two servo motors and ballscrews arranged symmetrically to balance torque and control thermal distortion, thus offering heavy duty cutting with optimal accuracy.

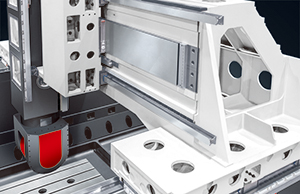

Super rigid headstock structure

• Two linear guideways with three sliding blocks each support the headstock. They ensure excellent machining accuracy even when the Z-axis is fully extended.

• The headstocks' multi-layered box structure design is light weight and highly rigid. It also offers excellent cooling properties, thereby ensuring optimal accuracy during long term precision cutting operations.

• The 24T / 30T chain type ATC imposes no force on the spindle bearings during tool changes, thus effectively extending the spindle's service life.

• The tool magazine is fully isolated from the work area. The auto door opens during tool changes only, thus preventing chips and coolant from contaminating the ATC mechanism, the tool magazine, and the tools and thereby ensuring long term tool change accuracy.