MACHINING CENTER w/ APC

In order to fulfill the needs for high efficient mass production capabilities, we use the BM / AF series combined with the APC system as a customized production plan. These series can reduce tool setting time during non-cutting conditions, provide fast table change performance and high-secure protection. This is your best choice for dealing with large work pieces under mass production.

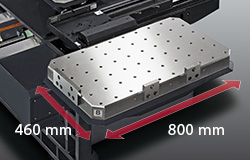

Table size

Table rotating range

Table load capacity

Japan Automobile Manufacture

using BM 850-APC in its Production Line

Famous for high quality automobile components, the Japanese automobile manufacturer has recently put the BM850-APC into its production line for producing inlet manifolds and gear box cases. They are satisfied with the high quality and reliable performance from our machines that are willing to purchase more for their production.

Face milling ( tool diameter Ø 200 mm )

BT 50 30-tool arm type ATC

| AF860-APC | AF860-APC | ||

|---|---|---|---|

| X / Y / Z axes travel | 860 / 600 / 600 mm | Spindle taper | BT40 |

| Table size | 460 x 800 mm | Spindle motor ( con. / 30 min. ) | 7.5 / 11 kW |

| Table rotating range | 180˚ | Spindle speed | 8,000 rpm |

| Repeatability for each table | 0.01 mm | X / Y / Z axes rapid feed rate | 48 / 48 / 32 m/min. |

| Repeatability between two tables | 0.02 mm | Cutting feed rate | 10 m/min. |

| Table load capacity | 200 kg | Tool magazine capacity | 24 T |